Several common faults that may occur in excavator engines and their solutions

上海华诚二手挖掘机市场 / 2024-05-25The excavator engine is the core power output of the entire excavator equipment. Each manufacturer uses many engine models, with different manufacturing processes and prices, which also leads to differences in the service life and stability of the engine. Generally, the engine failure rate of excavators is very low, and maintenance can be carried out according to the manual provided by the manufacturer, and stable working performance can be achieved within 10 years.

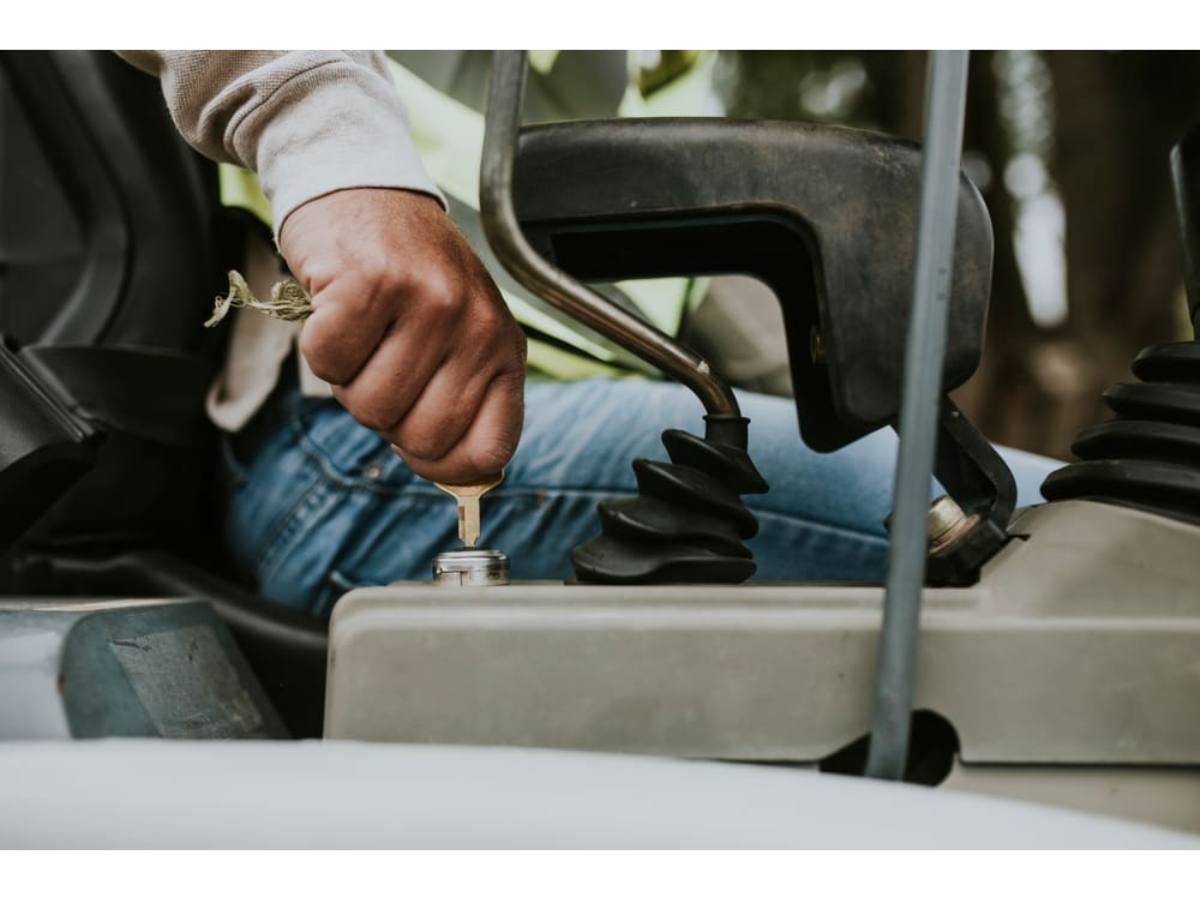

There will also be a certain defect failure rate here. These problems are not necessarily caused by the engine. Other indirect reasons or other uncontrollable reasons may also cause the excavator engine to malfunction. Here TD briefly explains several problems that may occur in daily excavator engines. If the core is involved, professional or experienced engineers must be arranged to operate.TD Used excavator

1. The engine is difficult to start or cannot be started:

- Check whether the battery voltage is sufficient and charge or replace the battery if necessary.

- Check whether the starter motor is working properly. If it is faulty, it needs to be repaired or replaced.

- Check whether there is air in the fuel system. If so, bleed the air.

- Check whether the fuel injection pump and fuel injector are clogged. If so, they need to be cleaned or replaced.

2. Insufficient engine power:

- Check whether the air filter is clogged. If so, clean or replace it.

- Check whether the fuel system is normal, such as whether the fuel injection amount is correct.

- Check whether the engine cylinder pressure is normal. If there is any abnormality, it may be that the cylinder is worn or the piston ring is stuck and needs to be repaired or replaced.

- Check whether the cooling system is normal. If the coolant temperature is too high, check the radiator, water pump and other components.

3. Abnormal engine noise:

- Determine the cause of the fault based on the location of the abnormal noise, such as abnormal noise from the crankshaft bearing, abnormal noise from the connecting rod bearing, etc.

- Check whether all parts of the engine are loose. If so, tighten them.

- Check whether the engine belt is loose or broken. If so, replace it.

4. Engine overheating:

- Check whether the coolant is sufficient. If it is missing, add it.

- Check whether the cooling system is smooth. If the radiator is clogged, clean it.

- Check whether the water pump is working properly. If it is faulty, it needs to be repaired or replaced.

5. The engine emits black smoke or blue smoke:

- Check whether the fuel injection volume is too large. If so, adjust it.

- Check whether the cylinder seal is in good condition. If there is leakage, repair or replace it.

- Check whether the turbocharger is working properly. If it is faulty, repair or replace it.

When we deal with an excavator engine failure, we can do a simple inspection. Of course, the inspection room needs to be step-by-step. According to the maintenance manual, if there is an abnormality in the engine, especially large-scale oil leakage, abnormal sound and violent fighting, please notify the engine immediately, and Arrange professionals to conduct inspections.

- First easy, then difficult: Check easy-to-solve problems first, and then troubleshoot complex faults step by step.

- Outside first, then inside: Start with the outside inspection and then work your way up to the internal components.

- Record the fault phenomenon: Detailed recording of the phenomenon when the fault occurs will help analyze the cause of the fault.

- Consult professionals: When you cannot solve the problem by yourself, promptly consult professional maintenance personnel or contact the manufacturer’s after-sales service.

The above content is for reference only. If you have any questions about the above issues, it is recommended to consult a professional maintenance organization for specific solutions.