Is it better to use electronic injection or direct injection for excavator engines? Which engine is suitable for you due to different working methods?

上海华诚二手挖掘机市场 / 2024-05-20Excavator engines have been updated and iterated on many products. During this period, many well-known engines appeared, and there were also some flaws. But now, with the requirements of excess environmental protection emissions in various countries around the world, electronic injection has basically become the standard configuration of excavator engines, but many people still prefer direct injection engines. Does it mean that direct injection has been eliminated? The answer is of course no. Some specific equipment still uses EFI engines. In particular, countries with different operating costs and technologies have huge differences in engine requirements.

Electronic injection engines and direct injection engines are two different internal combustion engine technologies. They have significant differences in fuel injection methods, combustion efficiency, emission control, etc. Here's a closer look at both engines, including their pros and cons.

EFI engine (electronic fuel injection engine):

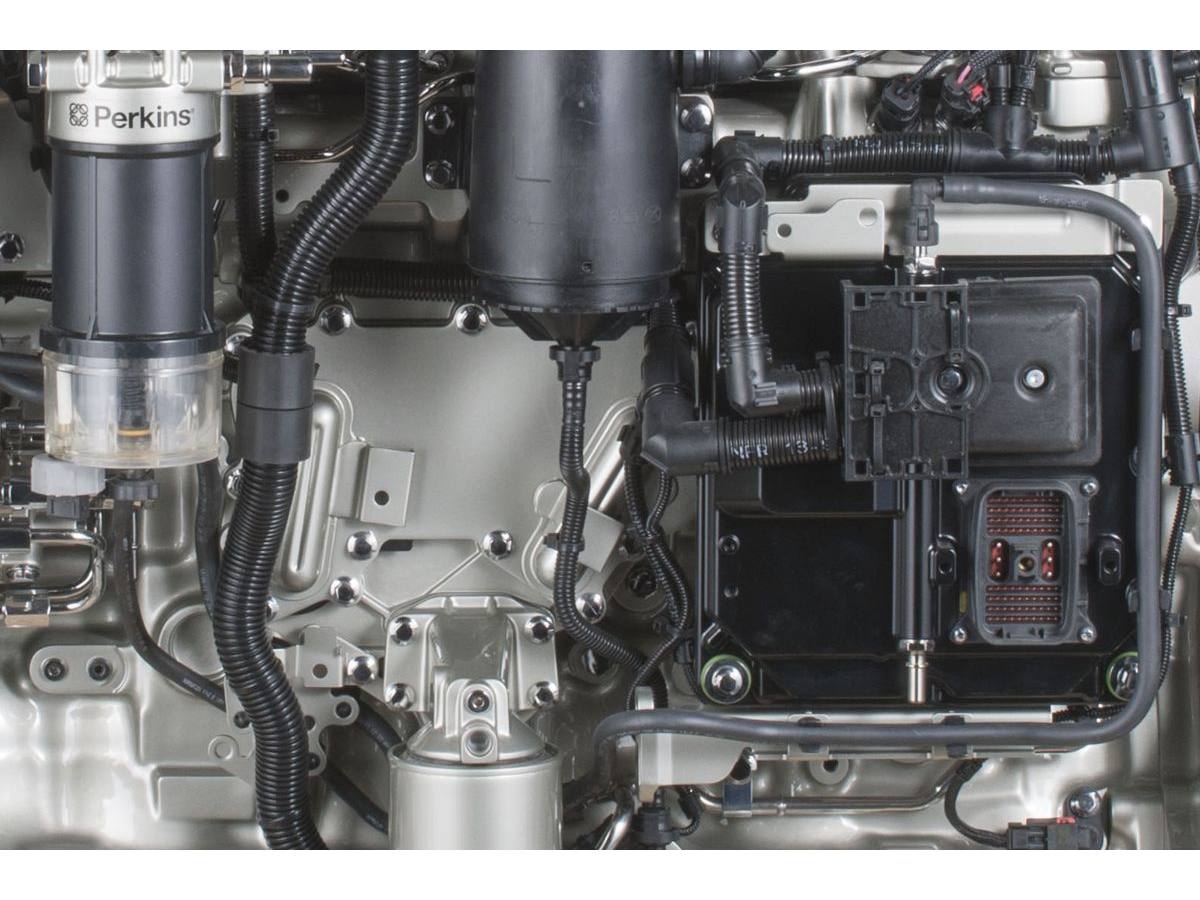

An electronic injection engine is an internal combustion engine that uses an electronic control system to precisely control fuel injection. In this system, the computer calculates the optimal fuel injection amount based on data provided by sensors (such as engine speed, intake air temperature, throttle position, etc.) and injects the fuel through the injector in a highly atomized form. Inlet duct or directly into the combustion chamber. This technology can improve fuel combustion efficiency, reduce emissions, and improve engine performance.

advantage:

1. Improve fuel efficiency: The electronic injection system can more accurately control the supply of fuel, ensuring that the best air-fuel ratio can be achieved under different working conditions, thereby improving fuel economy.

2. Reduce emissions: By precisely controlling fuel injection, EFI engines can effectively reduce harmful gas emissions and meet more stringent environmental standards.

3. Improve power performance: The electronic injection system can quickly respond to changes in engine load and provide smoother and stronger power output.

4. Easy maintenance: Since the control unit of the EFI system can self-diagnose faults and provide fault codes, maintenance personnel can more easily diagnose and repair problems.

shortcoming:

1. High initial cost: The components and control units of an EFI system are generally more expensive than a traditional mechanical fuel supply system.

2. Complex maintenance: Although diagnosis is easy, maintenance of the EFI system usually requires professional equipment and technical knowledge.

3. Dependence on the electrical system: EFI engines have high requirements for the stability and reliability of the electrical system. Any electrical failure may affect the normal operation of the engine.

Direct injection engines (direct fuel injection engines):

Direct injection engines are a technology that injects fuel directly into each combustion chamber. This design can reduce fuel flow losses in the intake passage, improve combustion efficiency, and allow a higher compression ratio, thereby increasing engine power and torque.

advantage:

1. Improve fuel efficiency: Direct injection technology can achieve higher fuel economy because it reduces fuel flow losses in the intake passage.

2. Enhanced power output: Direct injection engines usually have a higher compression ratio, which can produce more power and torque.

3. Fast response: The direct injection system responds faster and can instantly adjust the fuel injection amount to adapt to changes in driving conditions.

4. Reduce heat loss: Since fuel is injected directly into the combustion chamber, heat loss in the intake duct can be reduced.

shortcoming:

1. Emission control challenges: Direct injection engines may produce more nitrogen oxide and particulate matter emissions, requiring more complex emission control technology.

2. High fuel system requirements: Direct injection systems have higher requirements for fuel cleanliness and pressure, and require more precise fuel pumps and injectors.

3. Carbon deposit problem: Direct injection engines are more likely to form carbon deposits in the combustion chamber and may require regular cleaning.

For engine users, there is no need to worry too much. If the use environment is harsh, especially in remote areas or areas with poor maintenance conditions, you can buy a used excavator or a direct injection excavator. But for countries with high environmental protection and emission requirements, then EFI is an inevitable choice. Today, TD can provide different types of excavator models according to different user needs. It can even provide new or used excavator engines, which are not only cheap but can even provide various accessories for convenient maintenance.