Common problems and troubleshooting methods for excavator hydraulic pumps (need to be accompanied by staff with professional and technical experience)

华诚二手挖掘机市场 / 2024-05-26

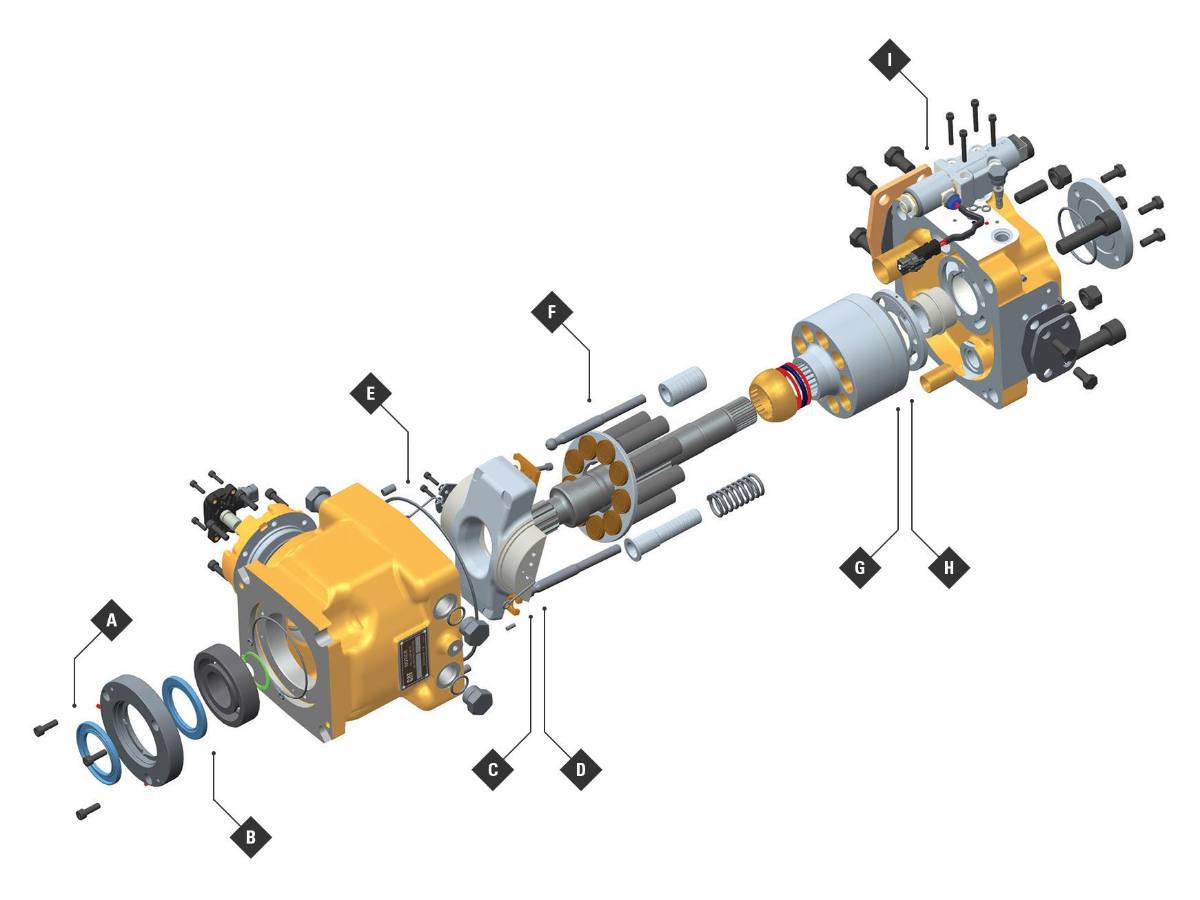

The excavator hydraulic pump and engine are the two core components that occupy the heaviest proportion of the entire excavator. Unlike the engine, hydraulic pump faults are more complicated. It is difficult for individuals to troubleshoot faults. Professional technicians are also required to repair the machine. The price gap between different manufacturers' hydraulic pump models is very large, and even the price gap of some hydraulic pumps can reach 1000%. Many people here are confused, is there a big difference in performance with such a high gap? In fact, the working performance of cheap hydraulic pumps is not much different, the main thing is the service life. If you are not afraid of trouble, a cheap hydraulic pump is certainly more cost-effective. Especially in harsh working environments or jobs that cause great damage to hydraulic pumps, such as hydraulic crushing, cheap hydraulic pumps do not put much pressure on them.

Today TD will briefly introduce to you several common hydraulic pump faults. Of course, we do not recommend that individuals without skills and experience replace and solve these faults by themselves. Of course, if you buy a second-hand excavator from TD, you can also buy a used hydraulic pump, which is also needed from time to time. Of course, they have all been tested and tested and there are no problems.

1. Abnormal noise of hydraulic pump: - Reasons for failure: Damage to the internal parts of the hydraulic pump, such as bearing wear, poor gear meshing, etc.; poor oil suction by the hydraulic pump, such as clogged filters, low oil level in the tank; leakage from the hydraulic pump, such as damaged seals. - Solution: Check and replace damaged parts; clean or replace the filter to ensure the oil level in the fuel tank is normal; check and replace seals.

2. Insufficient hydraulic pump pressure: - Cause of failure: Hydraulic pump efficiency decreases, such as pump body wear, valve plate damage, etc.; hydraulic system leakage, such as pipeline rupture, loose joints; relief valve set pressure is too low. - Solution: Repair or replace damaged hydraulic pump parts; check and repair leaking parts of the hydraulic system; adjust the set pressure of the relief valve to the specified value.

3. Insufficient hydraulic pump flow: - Reasons for failure: internal leakage of the hydraulic pump, such as excessive clearance between the plunger and cylinder, wear of the valve plate, etc.; hydraulic pump speed is too low, such as insufficient engine speed, broken pump shaft, etc.; blockage of the hydraulic system, such as bent pipes, valves, etc. Core stuck, etc. - Solution: Repair or replace damaged hydraulic pump parts; check and eliminate the cause of insufficient engine speed; clear the blocked parts of the hydraulic system.

4. Hydraulic pump overheating: - Cause of failure: The hydraulic pump has been overloaded for a long time; the temperature of the hydraulic oil is too high, such as cooling system failure; the hydraulic pump has serious internal leakage. - Solution: Avoid long-term overload operation of the hydraulic pump; check and repair the cooling system; repair or replace hydraulic pump parts with serious internal leakage.

5. Hydraulic pump cannot start: - Cause of failure: Hydraulic pump motor is damaged; power line failure; hydraulic pump control valve is damaged. - Solution: Check and replace the damaged motor; check the power line failure to ensure normal power supply; check and repair or replace the control valve.

Complex problems with the hydraulic pump may involve other parts of the excavator. Therefore, in addition to relying on experience and professional instruments to determine the problem, maintenance must rely on professional tools. The size and weight of the hydraulic pump can easily cause accidents. TD does not recommend personal disassembly. There are many accident cases that require vigilance.